diamond hazard label understanding risk at a glance takes you into the captivating world of safety signage where a single colorful diamond can reveal critical details in a heartbeat. Before you even step into a room or handle a chemical, this powerful label gives you the knowledge to make safe decisions and avoid potential mishaps. It’s more than just a sticker—it’s a universal language for safety, trusted by professionals worldwide.

The diamond hazard label is a standardized visual tool used to quickly communicate the specific hazards of chemicals and materials in workplaces, labs, and transportation. With its instantly recognizable diamond shape, distinct color sections, and numbered ratings, the label condenses complex safety information into an easy-to-read format. From its historical evolution to the strict international standards that govern its design, the diamond hazard label is essential for regulatory compliance and, most importantly, for keeping people safe.

Overview of Diamond Hazard Labels

Diamond hazard labels are a core component of workplace safety practices, offering at-a-glance information about the risks associated with chemicals and hazardous materials. These distinctive diamond-shaped signs convey critical data that helps protect workers, first responders, and the public from harm due to improper handling or exposure.

Originally developed in response to industrial accidents, diamond-shaped labeling systems have evolved alongside advances in material safety and international trade. The earliest versions date back to the mid-20th century, with the National Fire Protection Association (NFPA) introducing its iconic color-coded diamond in the United States. Over time, global standards, such as the Globally Harmonized System (GHS), have been established to create a more unified approach for hazard communication worldwide.

International standards such as NFPA 704 and the GHS provide detailed frameworks for the design, color, symbols, and numbering of diamond hazard labels. These standards ensure consistency and clarity, regardless of country or industry, which is essential for effective hazard communication in increasingly globalized supply chains.

Purpose and Significance in Workplace Safety

The primary role of diamond hazard labels is to warn and inform individuals about the potential dangers posed by substances stored, handled, or transported within a facility. By providing concise, standardized information, these labels help prevent accidents, facilitate emergency response, and ensure regulatory compliance.

“Diamond hazard labels serve as the universal language of chemical safety, bridging gaps between different industries, languages, and regulatory systems.”

History and Evolution of Labeling Systems

Diamond-shaped hazard labeling started as a method for fire safety and has since expanded its scope. Since the introduction of NFPA 704 in 1960, countries and organizations have adapted and built upon this format, leading to the adoption of the GHS in the early 2000s by the United Nations. This evolution reflects a growing recognition of the need for standardized hazard communication across borders and industries.

International Standards Summary

Key international regulations governing diamond hazard labels include:

- NFPA 704: Used primarily in the United States for fire and emergency situations.

- Globally Harmonized System (GHS): Adopted worldwide for chemical classification and labeling.

- ISO 7010: Includes standardized symbols for hazard communication supported by the International Organization for Standardization.

These standards detail label elements such as color coding, symbols, and numbering systems to ensure that important safety information is clear and actionable.

Design and Structure of Diamond Hazard Labels

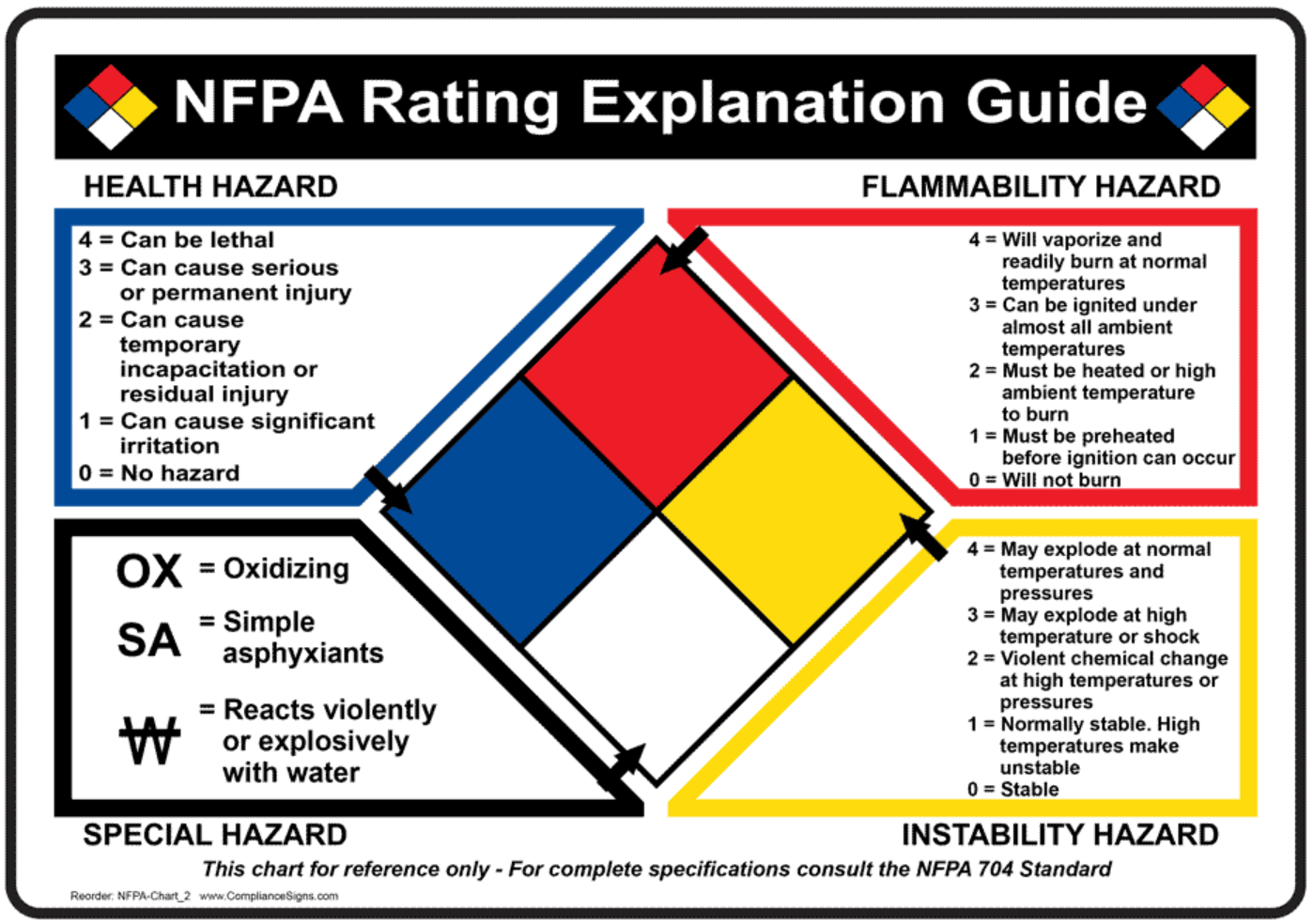

Effective diamond hazard labels use a specific color scheme, numbering, and symbol system divided into four quadrants. This structured approach provides quick visual cues about a substance’s health, flammability, reactivity, and special hazards.

Color Schemes and Their Representation

Each color on a diamond hazard label corresponds to a distinct type of hazard. The traditional NFPA diamond, for example, assigns:

- Blue: Health hazard

- Red: Flammability hazard

- Yellow: Reactivity hazard

- White: Special or specific hazard

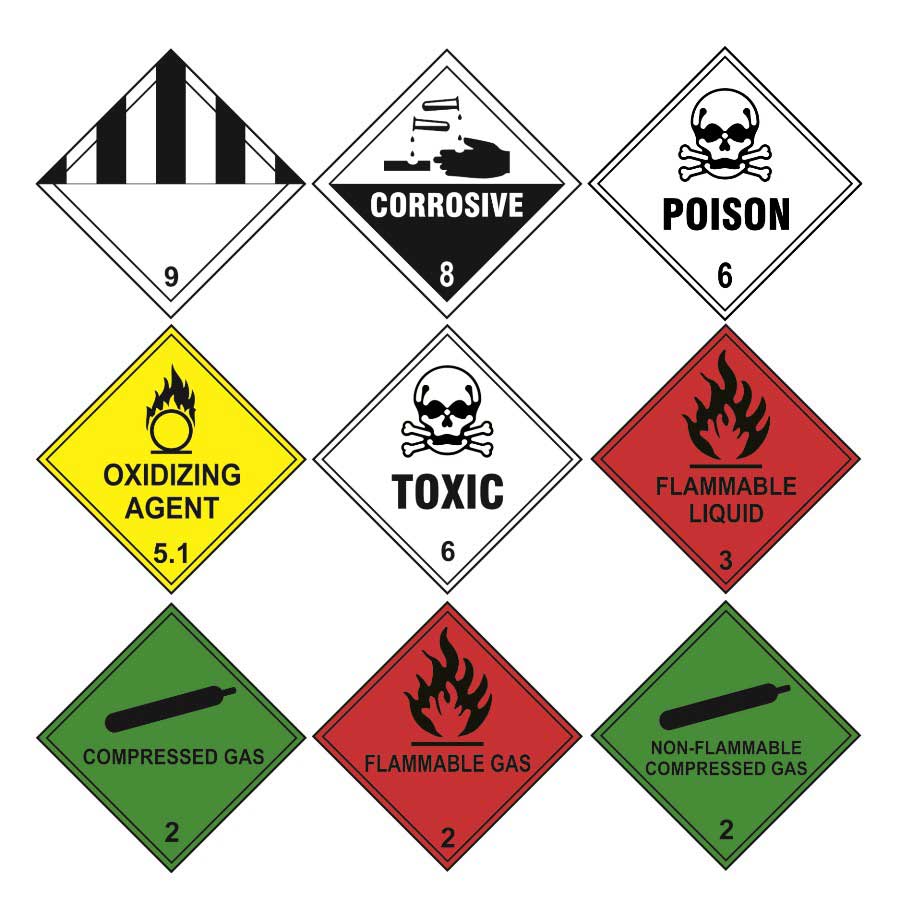

GHS labels also use red borders, but their pictograms and color usage differ based on hazard class and category.

Numbers and Symbols in the Quadrants

Numbers (usually from 0 to 4) indicate the severity or degree of risk, with higher numbers representing greater danger. Symbols in the white (bottom) quadrant denote special hazards, such as radiation or reactivity with water.

Diamond Label Quadrant Meanings, Diamond hazard label

The following table summarizes the standard design and interpretation of each section on NFPA diamond labels:

| Quadrant | Color | Symbol/Number | Meaning |

|---|---|---|---|

| Left | Blue | 0–4 | Health hazard severity (0 = none, 4 = extreme) |

| Top | Red | 0–4 | Flammability hazard (0 = will not burn, 4 = extremely flammable) |

| Right | Yellow | 0–4 | Reactivity hazard (0 = stable, 4 = may detonate) |

| Bottom | White | Symbol (e.g., W, OX) | Special hazards (e.g., reacts with water, oxidizer) |

Types of Diamond Hazard Labels

Different diamond hazard label systems are used across industries and regions, with the NFPA and GHS diamonds being the most widely recognized. Each type has unique design features and serves specific regulatory purposes.

NFPA and GHS Label Differences

The NFPA diamond is primarily used for quick hazard identification in emergency situations, while GHS diamonds are part of a global system for chemical classification and labeling in occupational and transport settings. The differences between these systems can affect how hazards are communicated and managed on-site.

- NFPA diamonds use color-coded numbers to indicate health, flammability, and instability hazards, plus special symbols.

- GHS diamonds use pictograms with red borders and specific symbols to denote chemical hazards, accompanied by signal words and hazard statements.

- NFPA is focused on emergency response; GHS is designed for comprehensive hazard communication in workplaces and during transportation.

- GHS labeling is required for chemicals sold internationally; NFPA is mainly used in the U.S. for storage/handling on-site.

Commonly Labeled Substances

Substances marked with NFPA diamonds often include flammable solvents like acetone, corrosive acids such as sulfuric acid, and compressed gases. GHS diamonds typically appear on containers of industrial chemicals, cleaning products, pesticides, and laboratory reagents.

Interpretation of Diamond Hazard Labels

Reading a diamond hazard label correctly is essential for maintaining safety and responding appropriately to emergencies. Understanding each quadrant’s meaning allows workers and emergency personnel to quickly assess risks.

Step-by-Step Decoding Process

The following steps Artikel how to interpret a standard NFPA diamond label:

- Start with the blue quadrant (left) to assess health hazards and necessary protective measures.

- Move to the red quadrant (top) to determine flammability risks and fire safety requirements.

- Examine the yellow quadrant (right) for instability or reactivity hazards, indicating potential for explosions or chemical reactions.

- Check the white quadrant (bottom) for special warnings, such as water reactivity, radiation, or oxidizing properties.

Sample Label Interpretations

A label showing Blue 3, Red 4, Yellow 0, and a blank white quadrant indicates: “Severe health hazard; extremely flammable; stable under normal conditions; no special hazard.”

A label with Blue 0, Red 1, Yellow 2, and a “W” in the white quadrant signals: “No significant health hazard; slight flammability; unstable with violent chemical change; keep away from water.”

Regulatory Requirements and Compliance

Diamond hazard labels must meet strict regulatory requirements to ensure consistent, reliable communication of chemical hazards. These rules are enforced by various agencies, depending on the country and industry sector.

Key Regulations by Industry

Regulations governing the use of diamond hazard labels include OSHA’s Hazard Communication Standard (HCS), the United Nations GHS, and local fire codes. Each mandates specific label features and maintenance requirements to safeguard workers and the public.

- Labels must be durable, legible, and prominently placed on all hazardous material containers.

- Elements such as hazard category, signal word, and precautionary measures are required for GHS compliance.

- Regular training on interpreting and using hazard labels is mandatory in many jurisdictions.

Mandatory Elements on Compliant Labels

A compliant diamond hazard label must include:

- Appropriate color-coded quadrants or pictograms

- Accurate numeric or symbol indication of hazard severity

- Special hazard information if applicable

- Supplier identification (for GHS labels)

Enforcement Agencies and Organizations

Several organizations ensure compliance with diamond hazard labeling standards, including:

- Occupational Safety and Health Administration (OSHA)

- National Fire Protection Association (NFPA)

- United Nations (for GHS implementation)

- International Organization for Standardization (ISO)

Methods for Creating and Applying Diamond Hazard Labels

Proper creation and application of diamond hazard labels are vital for their effectiveness. The type of material, printing technique, and placement can influence a label’s durability and legibility under various conditions.

Procedures for Printing and Affixing Labels

Labels are typically printed using durable inks on materials like vinyl, polyester, or laminated paper, depending on exposure risks. Once printed, they must be securely affixed to the surface of containers, tanks, or equipment, ensuring visibility and resistance to environmental factors.

Best Practices for Material Selection

Selecting the right label material ensures lasting adhesion and readability. For example, chemical-resistant labels are necessary for solvents, while UV-resistant labels are ideal for outdoor storage.

- Use polyester or vinyl for chemical and outdoor exposure.

- Laminated paper labels are suitable for indoor, low-risk settings.

- Prioritize adhesives designed for the material of the container (metal, plastic, glass).

Application Methods by Environment

The following table categorizes recommended application methods based on environment and hazard exposure:

| Environment | Recommended Material | Application Method | Use Case |

|---|---|---|---|

| Indoor | Laminated paper | Adhesive backing | Laboratories, storage rooms |

| Outdoor | UV-resistant vinyl | Self-adhesive, weatherproof | Shipping containers, chemical tanks |

| Chemical-Resistant | Polyester film | Solvent-resistant adhesive | Acid tanks, solvent drums |

| Temperature-Resistant | High-temp polyester | Heat-resistant adhesive | Process equipment, heated storage |

Common Mistakes and How to Avoid Them

Errors in the creation or placement of diamond hazard labels can undermine safety efforts and lead to regulatory penalties. Recognizing and addressing these mistakes is key to effective hazard communication.

Frequent Labeling Errors

Common mistakes include using faded or incorrect colors, missing quadrants or numbers, placing labels in hard-to-see locations, and using materials that degrade quickly under environmental stress.

Tips for Accurate and Visible Labeling

To ensure labels are correct and visible at all times, consider the following practices:

- Double-check all color codes and number assignments before printing.

- Regularly inspect labels for damage, fading, or illegibility.

- Place labels at eye level and on unobstructed areas of containers or equipment.

- Use high-contrast materials to enhance visibility in low light conditions.

- Provide periodic training for staff on label interpretation and placement.

Consequences of Incorrect Labeling

Improper hazard labeling can result in workplace accidents, chemical exposures, environmental contamination, and hefty fines from regulatory agencies. In severe cases, mislabeling has contributed to major industrial incidents, emphasizing the importance of rigorous label management.

Real-World Use Cases and Illustrative Scenarios: Diamond Hazard Label

Diamond hazard labels are utilized across diverse settings, from university laboratories and large-scale warehouses to freight vehicles transporting chemicals. Each use case demonstrates the label’s vital role in hazard communication and accident prevention.

Settings Where Diamond Labels Are Essential

In laboratories, diamond labels help researchers quickly identify which chemicals require special handling or pose immediate health threats. In warehouses, they aid in segregating incompatible materials and informing emergency responders. On transport vehicles, they provide crucial information during roadside incidents.

Illustrative Accident Prevention Scenario

Proper labeling played a crucial part in a 2022 incident at a chemical plant, where an NFPA diamond identified a substance as highly flammable. Firefighters were able to avoid using water and instead used foam, preventing a dangerous reaction and potential explosion.

Industry Comparison Table

The following table highlights the label’s role in different industry contexts:

| Industry | Label Type | Primary Function | Example Substance |

|---|---|---|---|

| Laboratory | GHS | Detailed hazard and handling info | Acetone |

| Warehouse | NFPA | Quick emergency response cues | Sulfuric acid |

| Transport Vehicle | GHS/NFPA (as required) | Regulatory compliance in transit | Compressed hydrogen gas |

Advances and Innovations in Diamond Hazard Labeling

Recent years have seen significant advancements in the technologies and materials used for diamond hazard labels. These innovations enhance safety, reduce costs, and streamline hazard communication processes.

Recent Technological Improvements

New label materials offer superior resistance to chemicals, abrasion, and extreme temperatures. Advances in digital printing enable full-color, custom labels with high-resolution symbols and text, improving legibility and adherence to standards.

Digital Solutions and Automation in Label Management

Digital labeling systems now allow for automated label generation and inventory tracking, reducing manual errors. QR codes and RFID tags are increasingly integrated into labels to provide instant access to Safety Data Sheets (SDS) and real-time hazard updates.

- Automated label printing for bulk operations

- Integration of QR codes for on-the-spot hazard information

- Cloud-based compliance management for multi-site operations

Future Trends in Hazard Labeling

Looking forward, the trend is toward smarter, more interactive labeling solutions. For example, the use of augmented reality (AR) for on-site hazard training is being piloted in the chemical industry. Additionally, regulations are expected to evolve to address new types of hazards, such as nanomaterials and advanced biohazards, requiring further adaptation of diamond label systems.