hazardous materials diamond is the unmistakable symbol you’ve probably seen on chemical containers, storage tanks, and facilities, instantly telling trained eyes what dangers may be lurking inside. This simple yet powerful color-coded design is more than just a warning sign—it’s a universal language that bridges the communication gap in high-risk environments, helping keep people and property safer in situations where every second counts.

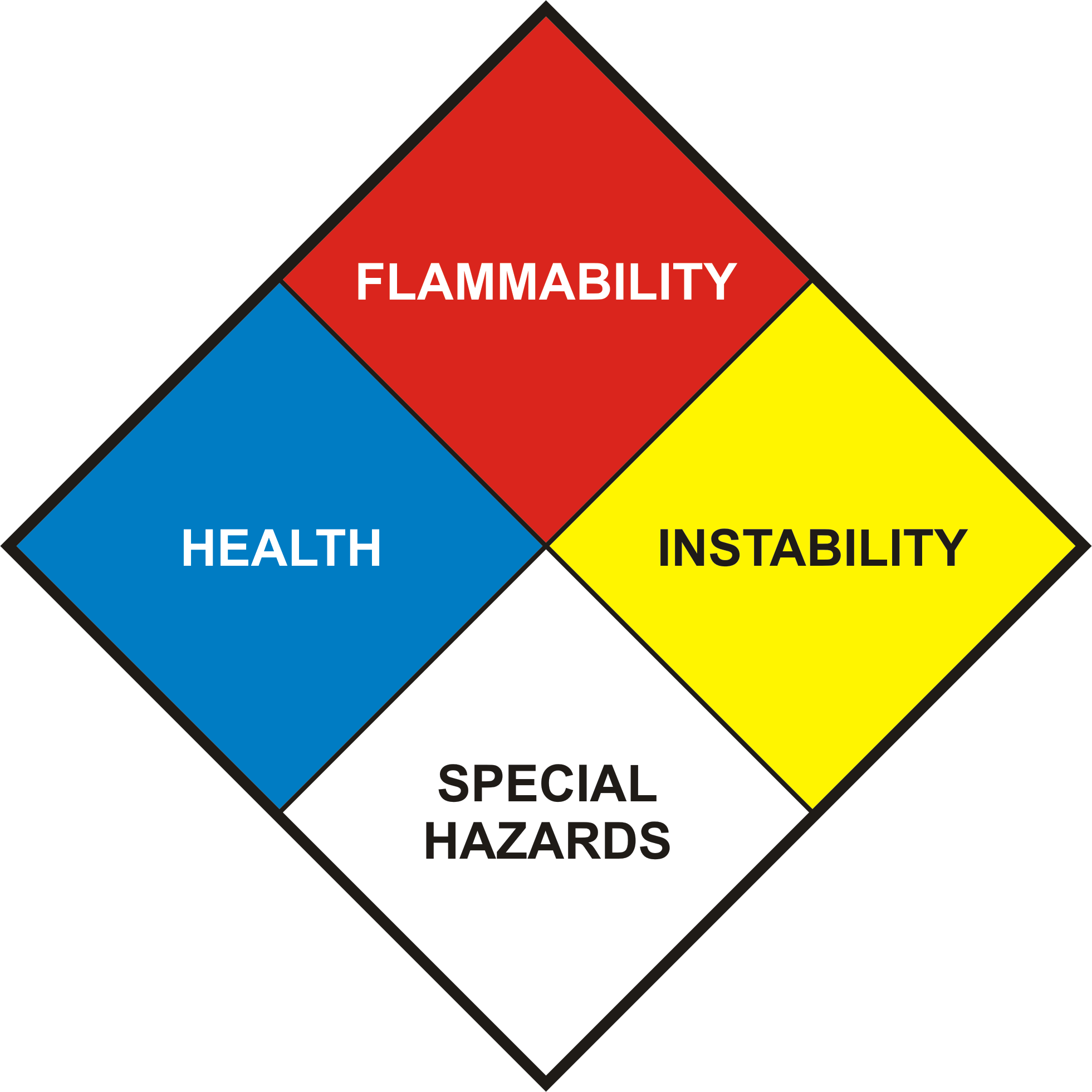

The hazardous materials diamond, also known as the NFPA label, was developed to provide clear, quick, and standardized information about potential hazards associated with chemicals. It breaks down hazards into four color-coded categories—health (blue), flammability (red), instability/reactivity (yellow), and special information (white)—each rated by severity to guide emergency responders and workers. The system’s widespread adoption by fire departments, industries, and regulatory agencies highlights its critical role in emergency preparedness and workplace safety.

Introduction to Hazardous Materials Diamond

The hazardous materials diamond, commonly referred to as the NFPA (National Fire Protection Association) diamond or fire diamond, is a vital labeling system designed to provide quick, at-a-glance information about the dangers of chemicals and materials during routine handling and emergency situations. Its primary aim is to safeguard emergency responders and employees by communicating critical hazard details instantly, often when seconds can make a life-saving difference.

Developed in the 1960s by the NFPA, the system arose from the need for standardized, easily recognizable symbols to indicate the types and severities of hazards posed by chemicals stored or transported in industrial, commercial, and laboratory settings. The clear, color-coded design allows even those with limited training to make initial safety decisions rapidly.

Organizations most frequently using the hazardous materials diamond include fire departments, emergency response teams, chemical manufacturers, laboratories, and facilities regulated by Occupational Safety and Health Administration (OSHA) in the United States. The diamond is also used globally in varying forms, particularly in industries handling volatile or toxic substances.

The Purpose and Significance in Safety and Emergency Response

The diamond’s immediate visual cues help responders quickly assess whether they need special protective gear, if evacuation is necessary, or whether specialized tactics are required to suppress a fire or handle a spill. This system reduces confusion and risk in high-pressure scenarios where clear communication is essential.

History and Development of the Hazardous Materials Diamond System

In response to increasing chemical use and several major industrial incidents, the NFPA formalized the diamond in NFPA 704, “Standard System for the Identification of the Hazards of Materials for Emergency Response.” The diamond has since become a benchmark in industrial safety labeling, with periodic updates reflecting evolving safety standards and hazard awareness.

Overview of Organizations Using the Hazardous Materials Diamond

- Fire departments and emergency medical services responding to industrial and commercial incidents.

- Manufacturing facilities storing, handling, or processing hazardous substances.

- Laboratories, both academic and commercial, managing diverse chemical inventories.

- Warehouses and logistics companies transporting regulated materials.

- Regulatory agencies and inspectors ensuring compliance with local and international safety standards.

Components of the Hazardous Materials Diamond

The hazardous materials diamond is divided into four distinct quadrants, each color-coded and numbered to signify a specific type of hazard. This design makes it easy to quickly determine the dangers associated with a material from a distance.

Four Color-Coded Sections of the Diamond

Each section of the diamond represents a different hazard category:

- Blue (left): Health hazard

- Red (top): Flammability hazard

- Yellow (right): Instability/reactivity hazard

- White (bottom): Special hazards and notations

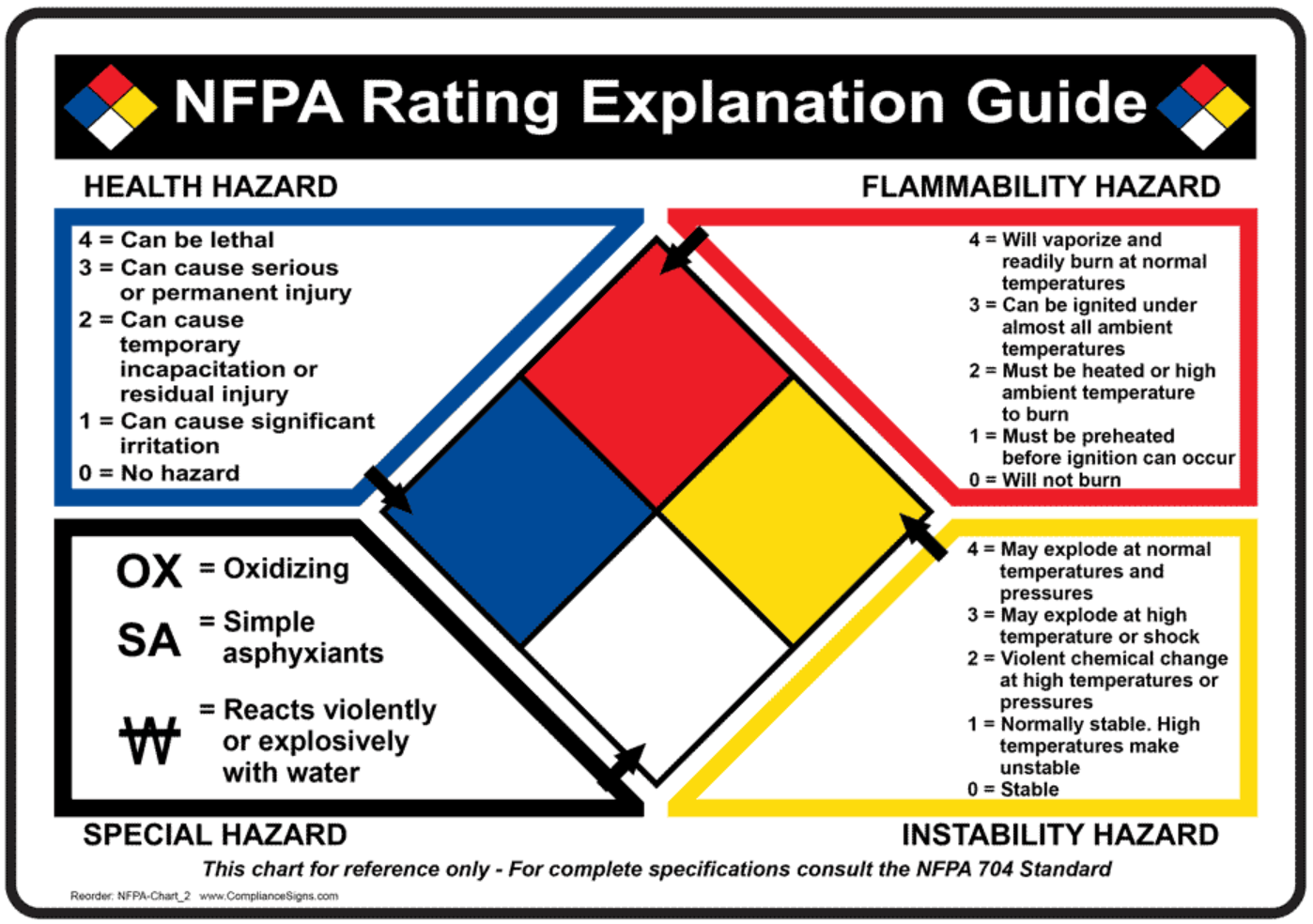

The blue, red, and yellow areas use a numerical rating from 0 (minimal hazard) to 4 (severe hazard), while the white section contains various symbols or letters indicating special precautions.

Hazard Type and Rating Scale Overview

A detailed breakdown of each section’s meaning, color, and rating range is provided below:

| Color | Hazard Type | Rating Range | Description |

|---|---|---|---|

| Blue | Health | 0–4 | Risk to health upon exposure (toxicity, potential for injury) |

| Red | Flammability | 0–4 | Susceptibility to catching fire under standard conditions |

| Yellow | Instability / Reactivity | 0–4 | Likelihood of a violent chemical change (explosion or reaction) |

| White | Special | Symbols / Letters | Special hazards (oxidizer, reacts with water, simple asphyxiant, etc.) |

Interpreting the Hazard Ratings

Understanding the hazardous materials diamond requires interpreting each section’s rating in sequence. This ensures that all relevant risks are considered before approaching or handling a material.

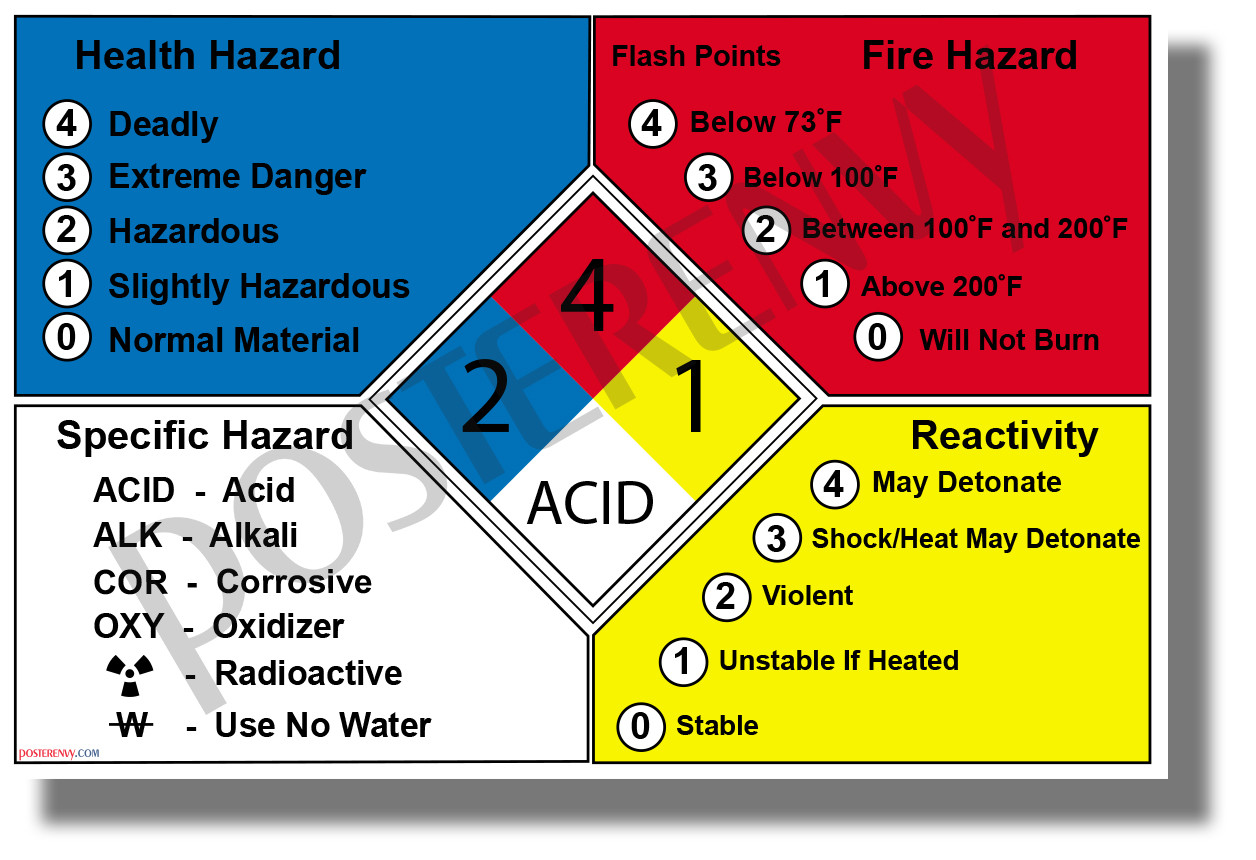

Step-by-Step Method for Reading the Diamond

First responders and facility personnel typically follow this method:

- Read the blue section (health hazard) to gauge personal protective equipment requirements.

- Check the red section (flammability) to assess fire risk and firefighting tactics.

- Examine the yellow section (instability/reactivity) for explosive or violent reaction potential.

- Note any symbol in the white section for special handling instructions.

Higher numbers (3–4) signal a greater degree of hazard, while lower numbers (0–1) indicate minimal risk.

Typical Hazardous Material Diamond Examples

The following table illustrates sample diamonds for commonly encountered materials:

| Material | Health (Blue) | Flammability (Red) | Instability (Yellow) | Special (White) |

|---|---|---|---|---|

| Acetone | 1 | 3 | 0 | |

| Sulfuric Acid | 3 | 0 | 2 | |

| Chlorine Gas | 4 | 0 | 0 | OX |

| Sodium | 3 | 3 | 2 | W |

A diamond with a “4” in any section signals a severe, immediate hazard, while a “0” indicates no unusual risk. Combinations such as “4-0-0” means extreme health risk but no fire or instability danger.

Implications of Different Hazard Ratings

Interpreting the numbers correctly can determine life-saving actions, such as the choice to evacuate, don specialized respirators, or avoid using water on certain substances. Thorough understanding of each rating is critical for effective emergency response.

Common Symbols and Special Notations

The white section at the bottom of the hazardous materials diamond is reserved for special symbols and notations that convey essential handling or response warnings not covered by the color-coded numbers. These symbols alert responders to unique risks that require specific procedures or precautions.

Special Hazard Symbols in the White Section

Some symbols frequently found include:

- OX: Denotes an oxidizer, which can greatly increase the rate of combustion and requires specific firefighting tactics.

- W (with a slash through it): Indicates the substance reacts dangerously with water, potentially causing fire or explosion if water is used for firefighting or cleanup.

- SA: Stands for a simple asphyxiant gas, such as nitrogen, argon, or helium, which can displace oxygen and pose a suffocation risk in confined spaces.

Other notations, such as “COR” for corrosive or “ACID” for acid, may be present depending on facility policy or local regulations.

Descriptions of Key Special Notations

Here’s a concise overview of the most common special notations:

- OX: Material is an oxidizer and can intensify fire.

- W: Material is water-reactive—do not use water in case of spill or fire.

- SA: Indicates a simple asphyxiant gas present; risk of oxygen displacement.

- ACID: Substance is acidic and may require acid-resistant equipment.

- ALK: Alkaline or caustic material; avoid contact with skin or eyes.

- COR: Corrosive chemical; use protective gloves and eyewear.

These notations are vital for ensuring that standard operating procedures are adjusted to address unique hazards.

Applications in Real-World Scenarios

The hazardous materials diamond is not just a theoretical tool—it is actively used in a wide range of real-life situations to improve safety and decision-making during emergencies.

Role in Emergency Response and Incident Management

When a chemical spill, fire, or leak occurs, first responders often rely on the diamond for immediate hazard assessment. This information shapes their initial entry, personal protective equipment selection, and approach to containment or evacuation.

Case Studies and Representative Scenarios

The following table summarizes realistic incidents where the hazardous materials diamond provided crucial guidance:

| Scenario | Hazard Diamond Displayed | Actions Taken | Outcome |

|---|---|---|---|

| Warehouse fire involving acetone storage | Health: 1, Flammability: 3, Instability: 0 | Firefighters used non-sparking tools and foam extinguishers to suppress the blaze | Fire contained rapidly, no injuries reported |

| Laboratory spill of concentrated sulfuric acid | Health: 3, Flammability: 0, Instability: 2 | Responders wore acid-resistant suits and neutralized the spill with sodium bicarbonate | Spill cleaned up safely, no chemical burns or exposures |

| Compressed chlorine gas leak in a water treatment facility | Health: 4, Flammability: 0, Instability: 0, Special: OX | Evacuation ordered, responders used self-contained breathing apparatus (SCBA) | No fatalities; area secured and ventilated |

These examples illustrate the diamond’s value in guiding quick, effective decisions during high-stakes incidents, reducing the risk of harm to people and property.

Impact of the Diamond in Everyday Facility Operations

Beyond emergencies, the hazardous materials diamond also plays a role in daily operations—serving as a constant reminder of necessary precautions, guiding safe storage, and supporting compliance with regulatory requirements.